Program Rules

In order to maximize the number of wooden drums that can be reused, we ask that only drums that comply with the following criteria are returned using the drum return program.

If a drum returned does not meet one or more of the criteria or is otherwise in a condition that cannot be reasonably reused, Dura-Line reserves the right to not accept the drum under the drum return program. See the brochure for responsibilities and full instructions.

Instructions

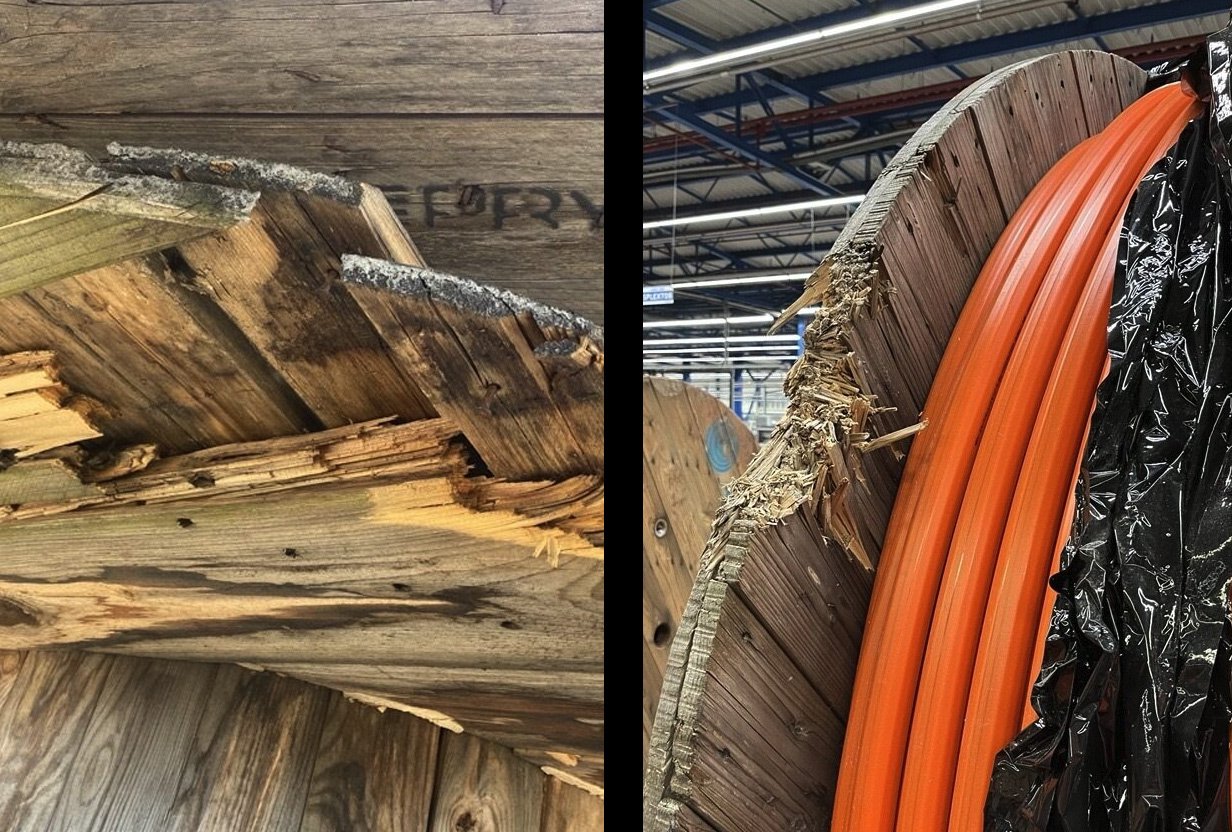

- The wooden drums shall be sound and free from defects that weaken the structure

- The wooden part shouldn't be rotten

- Drums shall be free from excessive splitting

- There should be no protrusion of nails or sharp objects on the drum

Dimensions

Only Dura-Line wooden drums and dimensions listed in the pickup form an be collected by Dura-Line.

Drum’s Condition

1. Core

Check the completeness and shape of the core. The maximum acceptable gap between boards in the core is 7 cm.

2. Metal Plate

For drums fitted with metal plates at the hub, check that plates are present on both sides and that they are also fastened.

3. Flanges

Check that flanges are straight, uncovered, and that nuts have been tightened. Ensure that flanges are tight to the drum.

Flanges should be unbroken, though small gaps may be accepted provided all elements are secured and are not scratched.

4. Screws

Check that threaded screws, washers, and nuts on flanges are all present.

5. Structure of the drum

The drum should be centered and not lopsided

Loading Instructions for Returned Empty Drums

- Only drums originally supplied by Dura-Line can be accepted under the drum return process.

- The loading area must be unobstructed and with enough space for a standard truck with trailer (16 x 4.1 x 2.5 m) to enter and manouvre safely and easily. The drums should be easily accessible and not stacked on top of each other.

- Suitable loading equipment (e.g., forklift) must be available at the return location and used for loading, e.g. forklift. Crane collection can be arranged but this is a non-standard service and may come at additional cost.

- Drums should be loaded into the trailer in the vertical flange position and sescured during transport (see images below for correct and incorrect drum loading).

- A collection may be postponed or refused in exceptional cases, such as a drum being in an inaccessible or remote location, or a lack of opportunity for Dura-Line to reuse a drum due to its dimensions

- The minimum pick up quantity is 3 Dura-Line drums